Valve Adjustment Made a Few Months Ago Now Needs Adjusting Again Why

Valve clearances are important, but having them done by your dealer can be very expensive; it's one of the chief reasons a lot of bikes are traded in. Merely ignore them at your peril as over time your engine can exist seriously damaged.

Before I bought my 1999 Kawasaki ZX-6R I'd never checked clearances on annihilation that didn't have a spiral and locknut, but now I've realised simply how simple information technology can be…

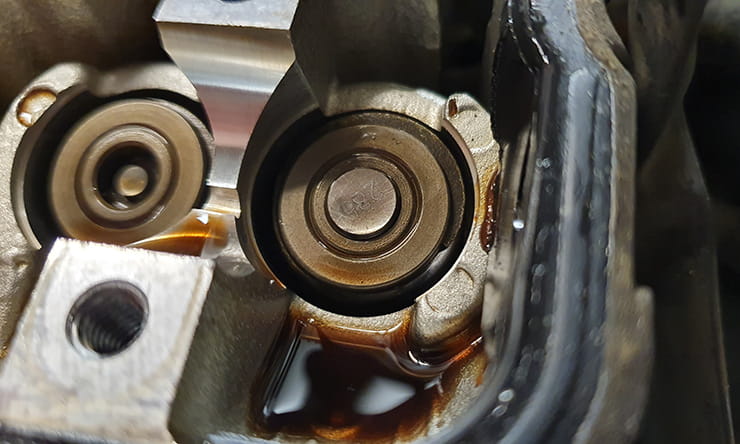

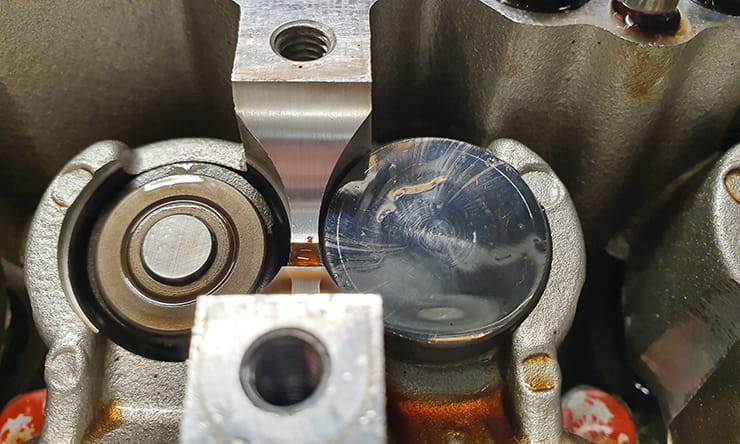

That footling metal disc looks so insignificant, but it's vital to maintaining a healthy engine

What are valve clearances?

Valve clearances on motorcycle and motorcar engines effectively relate to the gap between the top of the valve stalk and the cam that operates it.

The inlet valves in the engine open to allow air and fuel into the cylinder, while the exhaust valves let the burnt gases out. Needless to say, it gets hot inside the engine, so when the valves close, they shut onto a hardened 'seat', which acts every bit a estrus-sink. If the valves aren't completely airtight at the bespeak of ignition and the expansion of the called-for gases that push the piston down, the valves volition exist harmed and the high-pressure level gases can crusade serious and irreparable damage to the valves, the seats and other parts within the motor.

Why is it important to have a gap in valve clearances?

If the valve clearance was set to zero, the valve could theoretically however be set to close fully, but as the engine gets warm, the parts aggrandize; with no gap, the valve wouldn't close completely. That's why valve clearances MUST be checked with the engine stone cold.

How practise I know when my valve clearances need adjusting?

Incorrect valve clearances will atomic number 82 to poor running and, eventually, serious damage to your bike. You'll find plenty of forum and Facebook posts from people claiming that they didn't bother and their bikes are fine, but the damage will be progressive.

My ZX-6R hadn't suffered a hard life, but at just over xviii,000 miles, the exhaust valves were very tight. Personally, I'd always look for proof the clearances had been correctly dealt with on schedule when ownership any used motorcycle; information technology'south a sign of a caring owner and will give added conviction that the engine will last.

Shims don't need to be expensive, just getting to them is time consuming

What parts do I need?

If you're lucky, when you've checked the valve clearances, you'll find they don't need adjusting. The exhaust valves are the well-nigh likely to exist out, merely at that place is some tolerance; on my ZX-6R G2 for instance, the inlet valves should have a gap of between 0.xi and 0.19mm, while the exhaust valves should take between 0.22 and 0.31mm.

Chances are though, at least one of the gaps will need adjusting. Nosotros're focussing on saucepan and shim clearances here as information technology'southward the well-nigh common on modern motorcycles, so you'll need to buy some shims. The problem is, you'll not know which ones until y'all've measured them, so expect to have your bicycle off the road for a few days, unless your local dealer has them in stock.

I got mine from Wemoto, where for this bicycle they cost betwixt £2.20 and £4.85 each – if y'all bought them from Kawasaki they'd be £9.l each.

Yous'll besides likely demand some gaskets – the option-upwards coil encompass needs removing on my ZX-6R to gear up the position of the crank; a replacement gasket from Wemoto costs £iii.42 and is the genuine Kawasaki part.

The Haynes manual says that the four O-rings that seal the camshaft holder against the cylinder head should be replaced; every bit oil was leaking into the plug wells, I changed these at a cost of £i.75 each, along with the 4 gasket bearing caps that sit down on superlative of the camshaft holder at £5.17 each. The cam-concatenation tensioner O-ring should also exist replaced at £1.86. This bike had been stood for about ten years, so it's no surprise that some of the seals were failing.

If any shims do demand replacing, you'll need some fresh engine oil to lubricate them, only the chances are you'll be doing a full service anyway, so you should have it to manus.

What tools exercise I need?

This commodity is non intended to be all you need to adjust the valve clearances on whatsoever motorcycle. I'yard basing it on my 1999 Kawasaki ZX-6R, but your cycle will have its own unique needs, so I thoroughly recommend buying a Haynes workshop transmission first. My hope is that this will requite you the conviction to take on the chore for yourself, just only with a workshop guide specific to your auto will you have the correct procedure. Remember that Bennetts Rewards members can save a massive 40% on Haynes manuals at Bennetts Rewards. You'll also demand the post-obit…

- General tools to disassemble your bike

- Feeler gauge

- Micrometer

- Torque wrench

- Protective gloves

Brand sure your feeler judge covers the sizes you lot need to measure in increments of 0.01mm – I had to buy myself a new one, just information technology'south was merely £3.99 (and being a Bennetts Rewards member, I salve ten% on every purchase at Halfords).

Y'all really practice need a torque wrench if the shims need replacing as the camshaft holder is very delicate, and you'll also need a micrometer to measure the thickness of the shims that you remove. There's a hazard they'll accept their thickness engraved into them, merely none were legible on my cycle and you lot should bank check them anyhow. I got a loftier-quality Mitutoyo 103-137 for Christmas, which cost £46.99. You can pick upward cheaper versions, but I figured it was a lifetime investment. I'm sure my girl will thank me when I'm gone…

How do I check the valve clearances on my motorcycle?

If you're lucky, your wheel has hydraulic tappets, which automatically set the gap betwixt the cam and the valve (usually via a rocker arm), merely these are unremarkably only found in depression-revving engines like some Harley-Davidsons.

Screw and lock-nut adjusters tend to feature in smaller capacity bikes (like my Honda Grom MSX-125) and only crave a spanner and pliers to adjust, or you tin get a tool that holds the locknut while you plough the adjuster.

This is the tool I use to suit screw and lock-nut valve clearances on my Grom and the pit-bike I used to own, though there'south no space for information technology on the inlet of the Honda unless you remove the airbox

Near bikes utilise a bucket and shim – the cam presses on assembly, with the shim dictating the thickness of the pair – this is what we're looking at in this commodity. This bucket and shim so printing down onto the valve to open it.

Sometimes you lot'll find the shim on top of the bucket, but typically information technology's underneath it, which tends to be more reliable, peculiarly in high-performance motors.

A spring returns the valve to a closed position, unless you accept a Ducati, which is likely to have 'Desmodromic' valves. These utilise an arm to both open and close the valves, which is potentially more accurate, simply it as well means there are two shims for each valve.

Step 1: Ensure the engine is stone cold

This really is of import, so leave your wheel to cool overnight before starting work on it

Step 2: Strip the cycle down

To get to the valve cover on this bicycle, the fairing panels and tank need to come off, as well as the carbs. At that place are likewise panels on the side of the engine that demand to be removed.

To remove the carbs, the coolant needs draining every bit they're heated on this model – that might seem a pain, but you're likely to be conveying out a major service if you're doing the clearances.

I'd also removed the radiator as I was doing everything on the bicycle at the same fourth dimension, simply y'all tin can just remove the top bolts and lower it if you want.

Pace iii: Remove the cylinder caput embrace

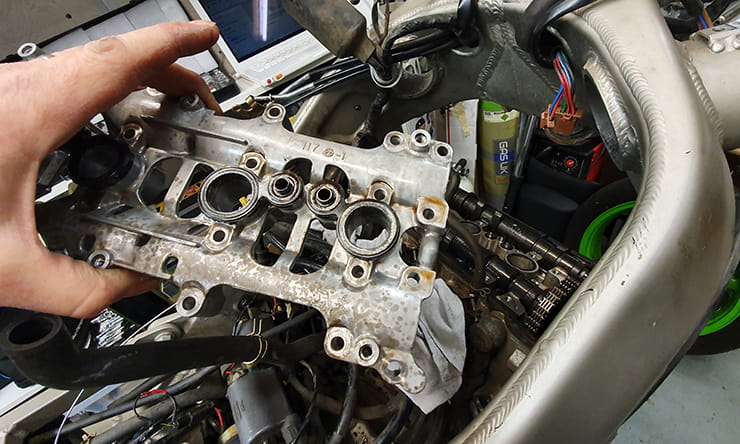

At that place are six bolts holding the cylinder head cover to the top of the engine – don't simply spin them out. Instead, turn each a small altitude at a time in a cross blueprint and then that the encompass is slowly and evenly released. It'southward bolted to the camshaft holder, which is fairly fragile.

Quick tip: Take care of the camshaft holder

The bandage aluminium camshaft holder carries the height begetting surfaces for the camshaft, but it's also what the camshaft comprehend bolts onto. It's vitally of import that yous take intendance when working with it, as it'south very piece of cake to damage. Don't enquire me how I know.

The problem is that this holder is machined to accept the camshafts while information technology's mounted to the cylinder head during manufacture; if information technology gets damaged, you demand to purchase a complete cylinder caput, unless you can automobile a new subclass that will fix the outcome – once again, don't ask.

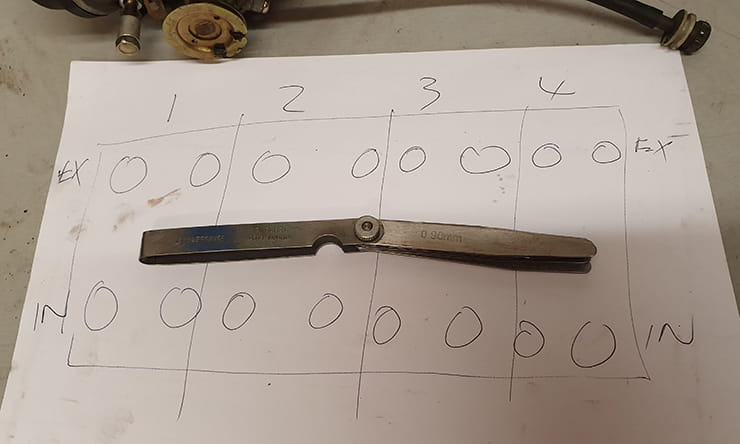

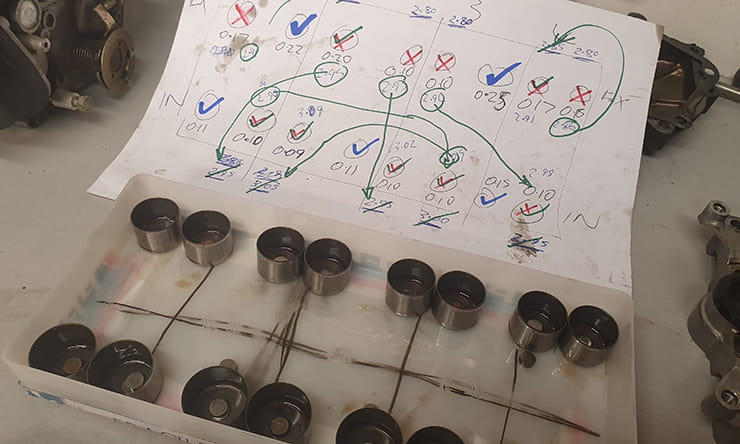

Step 4: Brand a chart

You demand to tape all the measurements you brand, so depict the layout on a piece of newspaper, making sure there'south no way you'll muddle it up.

Pace 5: Position the crank

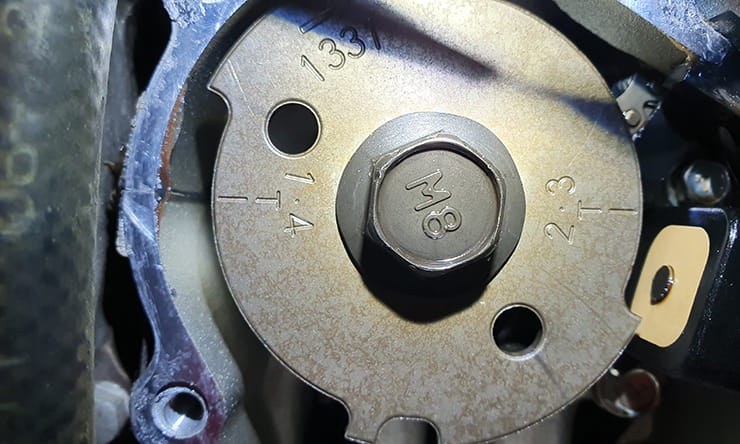

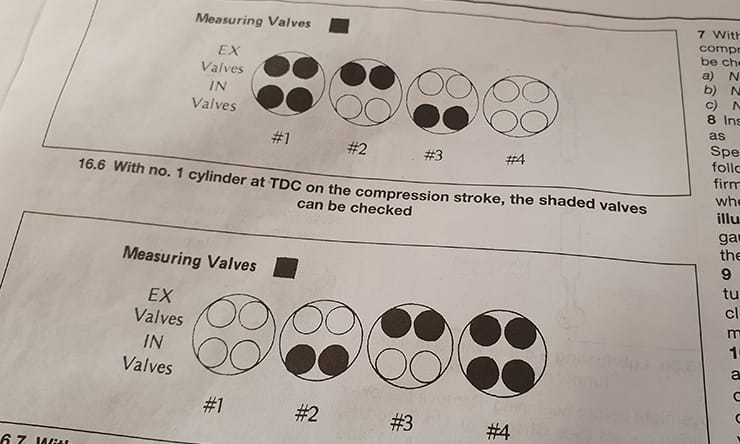

On this cycle, the pick-upwards whorl embrace on the correct of the engine needs to be removed, so a 17mm socket used to rotate the engine clockwise until the 'T 1.4' mark aligns with the two mating surfaces of the engine.

At this point, either cylinder number i (from left to correct as you lot sit on the wheel) or number for will be at tiptop dead centre (TDC) – that ways the piston is at the very top of its pinch stroke and the valves will be fully closed; this is the position at which the clearances need to be measured. If the cam lobes of cylinder one are facing away from each other and clear of the valves, then cylinder one is at TDC; if they're facing each other and pressing on the valve buckets, cylinder iv is at TDC. Your Haynes manual will tell yous which valves to mensurate in this position.

Step 6: Measure the kickoff set of clearances

In one case you know which valves to measure first, use your feeler judge to check the gaps. Set up your feeler gauge to the size it should be (you might need to combine two or more blades), and so poke it in between the cam and the bucket; you're feeling for a slight drag every bit y'all push information technology in and pull information technology out.

You lot'll discover information technology tricky at start, but keep trying thinner and thicker blades until you get a experience for it. One time yous accept it sussed, write the measurement on your piece of paper, making certain information technology corresponds to the correct valve

Quick tip: Do and oil

Effort a few combinations of blades when checking the valves; for example – if y'all think you need 0.05mm and 0.06mm for a measurement of 0.11m, check the gap with the 0.10mm single blade too; some of the thinner ones tin can fold upward, making it difficult to measure out. It'due south besides worth putting a wipe of clean engine oil on the blades so that they'll slide in.

Remember that there is a certain tolerance in the clearances, so don't get too hung upwardly on an dubiety of 0.01mm.

Pace 7: Measure the second set of clearances

Once you've taken the measurements of a total of eight valve on this 16-valve automobile, rotate the engine through 360° and then that the 'T 1.4' mark aligns again. The other cylinder should exist at TDC and you can now measure the remaining valve clearances.

If you're lucky, all of the clearances will be inside the specified tolerances so you can put the bike back together and get for a ride. Chances are though, at least i gap will exist tight – probably on the frazzle – so mark whatsoever that are out conspicuously on your slice of newspaper…

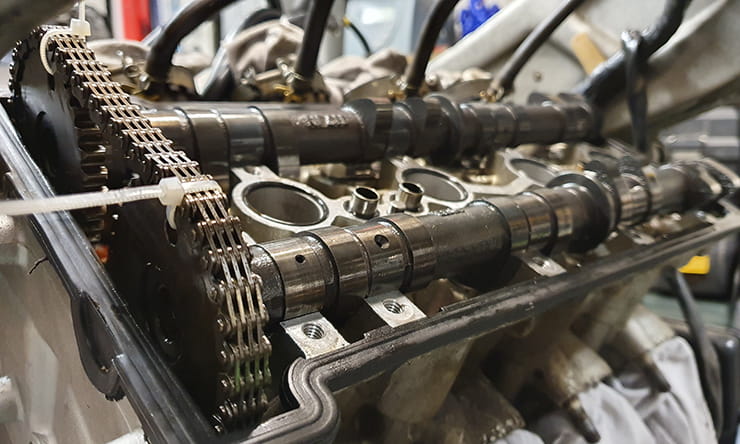

Holes in the camshafts can be used to tie the concatenation in place but you have to exist VERY conscientious not to harm it

How do I adjust the bucket and shim valve clearances?

The camshafts on this bicycle should exist removed with the T 1.4 mark all the same aligned with the engine mating surfaces, just if you want to necktie the concatenation to the camshafts, rotate information technology 360° until the holes in the gears are exposed at the summit. Make certain you lot rotate the camshafts earlier removing the holder, and ensure you align the T one.4 mark.

Step 8: Remove the cam-chain tensioner

The cam-chain tensioner has a spring in it that pushes a plunger against the chain, simply it's on a ratchet that can't return so NEVER partially unscrew the adjuster and then tighten information technology back up.

First unscrew the central bolt in the tensioner almost all the way out to salvage the pressure, and then you can remove the tensioner body itself.

Step 9: Remove the camshaft holder

There are ten bolts holding this camshaft holder down and it'southward surprisingly fragile – information technology'southward very important that you undo each bolt a niggling at a fourth dimension in a criss-cross pattern; the valve springs are pushing some of the cams upwards, and so the camshaft holder can be hands distorted or fifty-fifty croaky. Bad times.

One time it'southward off, check the bearings surfaces for clothing or damage.

Stride 10: Remove the cams

The cams are labelled 'IN' and 'EX' on the heart of the shaft (they have both 'IN' and 'EX' on the gear at the end, which can be confusing) – don't muddle them up. You tin can lift the cam concatenation off the cams then remove them, only you must employ something to avoid dropping the concatenation downward into the engine; I used a piece of pipe.

Some other selection is to zilch-tie the chain to the cams; this can be particularly handy if you lot just need to remove a couple of shims, but you must be very careful not to twist and damage the concatenation; this is something of a bodge, but it helped me out on the fifth time I had to remove a cam (please, don't inquire).

Y'all should check the bearing surfaces and lobes for any signs of wear or damage.

Footstep xi: Remove the shims

You only need to remove the shims from the valves that have wrong clearances. I constitute it easiest to get them out using a magnet, which lifted the bucket and the shim with it.

Place the bucket in the corresponding spot on your slice of newspaper or in a tray so you tin proceed rail of what you lot're doing. It'southward actually important that you DO NOT muddle these buckets or shims upwards, so have a articulate working space and make certain null can get knocked, specially if it's going to be a few days before they become back in.

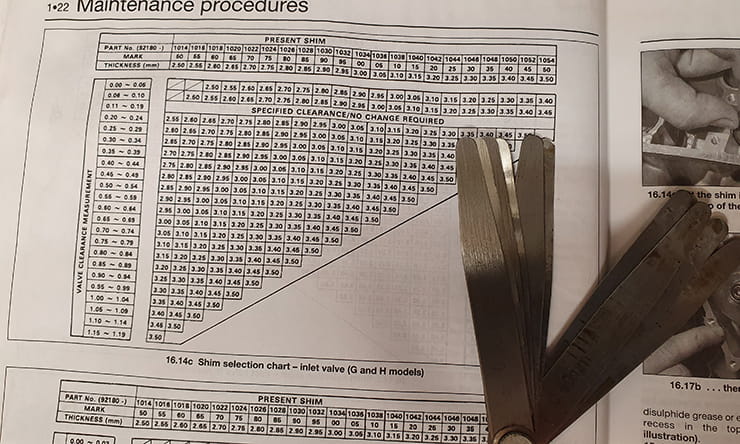

Stride 12: Measure the shims

Shims come with a size mark on them, but at that place's a practiced take a chance it will take worn away and you should cheque them anyway using a micrometer. Mensurate each shim ane by one and write the size next to the gap you measured.

Using the chart in the Haynes manual, yous tin then use the gap measurement and the nowadays shim to find the size of shim you need. It sounds complicated, simply once you have the numbers it makes sense – For instance, a gap of 0.10mm falls into the 0.07-0.11mm range on the nautical chart. Given that the present shim is 2.95mm thick, we can run across on the nautical chart that a 2.80mm shim is required; that'south what y'all need to buy.

I was able to swap some shims around from incorrect clearances to reduce the number required. Yep, this looks complicated, but all that matters is that when you do the work, you know which numbers are which. I institute that some of the existing shims that were in wrong gaps were the sizes I needed for other valves, which saved some money – I just needed four new shims instead of 11.

If you place your order in time with Wemoto, y'all could get them the next 24-hour interval, but give yourself time to get the parts in and reassemble the wheel, and keep the open engine covered up.

A shim in place on the left, with the bucket replaced on the right

Step 12: Refit the buckets and shims

Once you have the new shims, lubricate them with fresh engine oil and pop them into the tops of the valves, then slide the oiled buckets dorsum over. Make sure you practise ane at a time, and so you can't muddle them up.

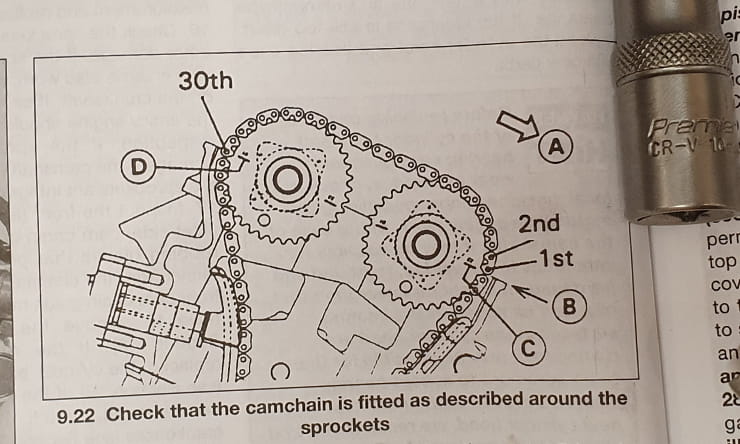

Footstep 12: Fit the cams

Oil the cylinder head'south bearing surfaces so, making sure they're on the correct sides, refit the cams. You lot need to fit the chain to the exhaust cam first, pulling information technology taught at the forepart of the engine with the T 1.four marking lined upward with the engine casing joints and the 'EX' line on the exhaust camshaft's gear lined up with the top of the engine casing. And then fit the intake cam with the chain tight between the two gears and the 'IN' line matching the top of the engine casing. On this bike, at that place needs to be thirty chain links between those ii lines on the gears, to ensure the concatenation is correctly fitted.

Step 13: Commodities the camshaft holder back on

Wipe some fresh engine oil on the bearing surfaces, bank check the O-rings are in adept condition and correctly aligned, then locate the camshaft. It's vital that you tighten downward all ten bolts very gradually and in a criss-cross pattern. Take your time and use a torque-wrench for the terminal tightening – on this wheel information technology's merely 12Nm.

Step 14: Refit the cam-chain tensioner

Without refitting the spring and commodities, reset the tensioner by belongings downward the ratchet and pushing the plunger all the way dorsum into the body (the O-band should be replaced). Bolt the tensioner body back into the engine, and then, after checking the status of the sealing washer, insert the leap, bolt and washer – every bit information technology's tightened, you'll hear the plunger push button out. Bank check the cam-chain is tight and rotate the crankshaft through two full turns, and then check once again.

Step 15: Measure the valve clearances again

The moment of truth – post-obit the same process as you did before, check all the valve clearances. Fingers crossed yous didn't miss-measure in the get-go place as it's really frustrating to have to take it all apart again then club more shims (again, don't inquire).

Step 16: Refit the cylinder head cover

Check the gaskets and supervene upon if necessary. Still using a gradual cross-cantankerous pattern, refit the cylinder head encompass. Then put everything else back together and be proud of the fact that yous've completed one of the most challenging maintenance jobs on a wheel. Great work!

If you can't do this job yourself, your dealer will be happy to take the work on. While prices volition vary, Nick Nomikos, possessor and MoT tester at The 2 Wheel Heart in Harpenden (too equally our technical advisor) says he'd charge £198 to check the valve clearances, plus around £66-£100 if they need adjusting. Prices include VAT, but non parts.

Source: https://www.bennetts.co.uk/bikesocial/news-and-views/advice/bike-maintenance/how-to-check-adjust-valve-clearances-motorcycle

Post a Comment for "Valve Adjustment Made a Few Months Ago Now Needs Adjusting Again Why"